1000L/13000L/2000L Vacuum Emulsifier Mixer (hydraulic lifting)

Principle of Vacuum Emulsification

It refers to the rapid and uniform distribution of one or more phases into another continuous phase using a high shear emulsifier in a vacuum state, utilizing the strong kinetic energy brought by machinery to enable the material to withstand hundreds of thousands of hydraulic shear cycles per minute in the narrow gap between the stator and rotor. Through the combined effects of centrifugal extrusion, impact, tearing, and other processes, the emulsion is instantly and uniformly dispersed. After high-frequency cycles, high-quality products with no bubbles, delicate texture, and stability are finally obtained.

Product Name: Vacuum emulsifier mixer/various Cream production line

Keyword: Vacuum homogenizing emulsifier/hydrocortisone mixer, high shear homogeneous emulsifying machine, Cream production line

Introduction: 1. Use in hydrocortisone cream, ointment, emulsion series products:

2. Work by homogenizer, fixed stirrer, scrapers residues stirrer

Formation:

ZJR Vacuum Emulsifying Mixer Series is composed of emulsification boiler(fluctuating cover, overturn kettle form or outside circle form), water boiler, oil water, vacuum system, heating and temperature control systems, cooling systems, electric machinery control systems. etc.

It can make various facial cream, lotion, shower, ointment, shampoo, paste, gel, honey, meat, milk, sauce etc.

Features:

The pot cover is automatic rising type, the material was directed draw into the emulsifying boiler from oil boiler and water boiler based on a pipe that is under vacuum, the discharge is based on the turn the emulsifying boiler. And the heating system is electric heating or steam heating that the temperature is automation control. Put the cool water into the intercalated bed so cooling the material, simple operation and safety( at the outside have a warm layer). The homogenizer and the blade stirring can together work or separate work. The material sliming, emulsification, mixing, dispersing, etc. What will finished during short time. Contact position adopt high-quality stainless steel (medical use adopt 316L material make with supplies, the polishing of surface of the mirror of interior surface, mix the hygiene of the device in vacuum, it accords with the normal hygiene standard manufacture of GMP to adopt that is most ideal production equipment. ).

Name | ZJR-1000 | ZJR-1300 | ZJR-2000 | |

Emulsifying Pot | Design Volume (L) | 1000 | 1300 | 2000 |

Capacity (L) | 800 | 1000 | 1600 | |

Scraper Stirring Power (KW) | 4 | 4 | 7.5 | |

Scraper Stirring Speed (rpm) | 0-45 | 0-45 | 0-45 | |

Homogenizer Power (KW) | 15 | 18.5 | 30 | |

Electrical Heating Power (KW) | 24 | 24 | 30 | |

Homogenizer Speed (rpm) | 2800 | 2800 | 2800 | |

Water Pot | Design Volume (L) | 650 | 800 | 1200 |

Capacity (L) | 500 | 650 | 960 | |

Power (KW) | 1.5 | 1.5 | 2.2 | |

Speed (rpm) | 960 | 960 | 960 | |

Electrical Heating Power (KW) | 18 | 18 | 24 | |

Oil Pot | Design Volume (L) | 500 | 650 | 950 |

Capacity (L) | 400 | 500 | 760 | |

Power (KW) | 1.5 | 1.5 | 2.2 | |

Speed (rpm) | 960 | 960 | 960 | |

Electrical Heating Power (KW) | 18 | 18 | 24 |

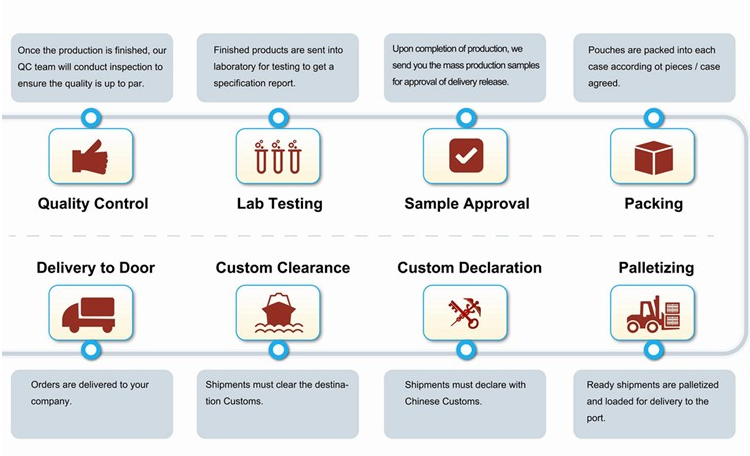

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)