Automatic Capsule Filling Machine with Vacuum Loader (NJP1200C)

Fully Automatic Capsule Filling Machine is an intermittent operation multi hole plug metering fully automatic closed filling equipment, which can automatically complete various processes such as bag sowing, bag separation, filling, waste bag removal, bag locking, finished product export, particle filling, etc. It has the advantages of reliable positioning, accurate filling volume, and high yield. Suitable for automatic filling of powdered and pellet shaped capsule drugs, it has passed provincial technical appraisal and meets GMP standards.

There are two types: regular type and human-machine interface improved type. The improved model adds touch screen control, PLC programmable controller, intelligent module, and fiber optic detection on the basis of the ordinary model, which has the characteristics of easy and intuitive operation. Important components are imported and have a high degree of automation.

NJP1200C fully automatic capsule filler with vacuum loader for powder or capsule

Fully automatic capsule filling machine - pharmaceutical industry equipment

This machine is an intermittent operation multi hole plug metering fully automatic closed filling equipment, which can automatically complete various processes such as bag sowing, bag separation, filling, waste bag removal, bag locking, finished product export, particle filling, etc. It has the advantages of reliable positioning, accurate filling volume, and high yield. Suitable for automatic filling of powdered and pellet shaped capsule drugs, it has passed provincial technical appraisal and meets GMP standards.

There are two types: regular type and human-machine interface improved type. The improved model adds touch screen control, PLC programmable controller, intelligent module, and fiber optic detection on the basis of the ordinary model, which has the characteristics of easy and intuitive operation. Important components are imported and have a high degree of automation.

Features and Functions

1. We get many patented technologies on this fully automatic capsule filling machines.We research and design the capsule filling machines on the basis of absorbing and improving advanced technologies in the world by ourselves.

2. It is a fully automatic capsules filling machine. The machine can complete the following processes automatically including feeding capsules, opening capsules, filling drugs, rejecting unqualified products, closing capsules, outputting products, cleaning molds.

3. Our machines meet GMP, ISO, CE standards.

4. Fully automatic working principle decreases cost of human consumption but increases production efficiency.

5. Totally closed working station keeps environment dustless, clean and sanitary and safe.

6. PLC and touch screen makes high precision, easy operation, clear display.

7. Imported electrical equipments and bearing main parts guarantees stable, high efficient and precise performance.

8.12 months guarantee and we can send engineer to customer factory for installation,commissioning machines,training customer's technicians.We also offer good after sales service,offer spare parts in time.

9. Material contact part is made of stainless steel 304 or 316L as option.

| Technical Specifictions | |

| Model | NJP-1200C |

| Capacity | 72000capsules/h |

| No. of segment bores | |

| Machine weight | 1100kg |

| Machine Dimension | 910*980*1800mm |

| Power supply | 220/380V, 3 PHASE, 50/60 HZ (For customer to designate) |

| Motor Power | Motor 1.5kw Vacuum 2.2kw Dust 2.2kw |

| Vacuum | 40m 3 /h-0.04-0.08Mpa |

| Dust | 24.5Kpa 210 m 3 /h |

| Noise | < 80DB (A) |

| Making rate | Empty capsule 99.9% Full capsule over 99.5% |

| Capsule size | 00#-5# |

| Filling error | ± 2.5%-3.5% |

| Powder vacuum loader | QVC-1, capacity 350kg/h, compressed air pressure 0.5-0.6MPa and consumption 180L/min |

| Capsule vacuum loader | QVC-2, capacity 700kg/h, compressed air pressure 0.5-0.6MPa and consumption 360L/min |

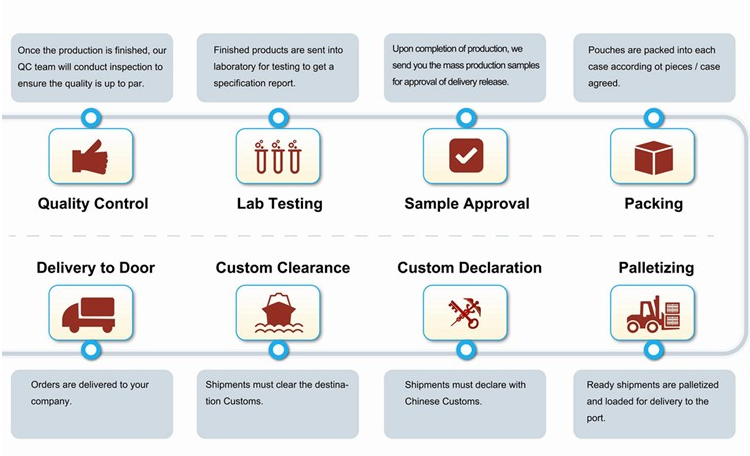

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What’s the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment, and D/P is acceptable as well.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)