Hifh Efficient Film/Sugar Coating Machine (BG-400)

The machine is applied for coating the organic film, water soluble film and sugar on tablets.

PLC & Touch screen controlled and GMP standard.

Put the tablet or pellet into the coating drum, the tablet or pellet unceasingly moves in the clean and hermetic rotating coating drum. In the movements, with the requests of reasonable process parameters, coating medium is automatically sprayed, at the same time, hot air is supplied under a negative pressure, which is vented out through the tablet or pellet layer from the bottom of the coating medium sprinkled on the tablet or pellet surface gets dried promptly and equally with forming a solid and smooth surface film.

Features:

1. As required by the standard of GMP, the quantitative index instruction operation is applied as possible as it could in the medication production process.

2. Under the streamline diversion plate blender's effect, the prime pistil overturns fluently, exchanges frequently and excludes the collision phenomenon when the prime pistil falls from high, settles the fragment and knocked edge and enhances finished product ratio. Surface of the diversion plate is narrow and small with excluding adherence of dressing to its surface, saving the dressing and improving medication quality.

Detailed Product Description

Applications:

This coating machine is used for coating tablets, pills, candy, and chocolate. Makes solvent film coat

The coating machine is adopted with novel. Micro-computer PLC and Temperature Model Control System, touching screen to display, ease of operation, high efficiency and saving energy, cleaning and safety, accord with the requirement of GMP, it is widely used in pharmacy as well as foodstuff industry, and it is an ideal euipment for tablet, pill, candy, chocolate etc to make solvent film coating, organic film coating, sugar coating.

2. Main Machine:

It is adopted with imported stainless steel to be made, with cleaning device, computer control, controllable program function, touching screen display.

3. Schematic principle:

The core will make orbital motion continuously in the clean and sealed rotating roll with many small holes, with the help of plate mixer, turning freely, exchanging fluently, follow the process flow and rational parameter, coating automatically, simultaneously hot wind will be exhausted from the bottom of the holes under the negative pressure of the air exhauster to make the coating medium dry quickly and form a smooth and hard surface of coating medium.

| Main technical parameter | Main technic explanation | |

Max.capacity(kg/batch) | 400 | 1.main machine: PLC man-machine interface,high-efficiency,save energy source , no dust, no pollution, easy to operate and wash , small noisy . pills are clothed: the clothing dry, symmetrical, hard, thick,Smooth 2. hot-air dryer: passed three steps to filtrate of primary-Middle-senior,hot-air clean level has reached 100 thousand . 3.exhaust blower:has the devices of shockproof and automatic dust removing 4. adopt japan import spray gun (five) 5. isobarically grout mixer tank 6. burette 7. strong electrical tank 8. wind pipe: 10M 9. this installment accord to "GMP" standard 10. this installment have passed provincial science and technology checkup 11.PLC adopts Siemens and touch screen adopts Japan digital pro-face. |

Coating drum Rotating speed (r/min) | 1-18 | |

Motor power of Main machine (kw) | 3.0 | |

| Flow capacity of Hot-air dyer (m3/h ) | 1688-3517 | |

| Motor power of Hot-air dyer (kw) | 3.0 | |

| flow Capacity of exhaust Blower (m3/h ) | 5712-12062 | |

motor power of exhaust blower (kw) | 7.5 | |

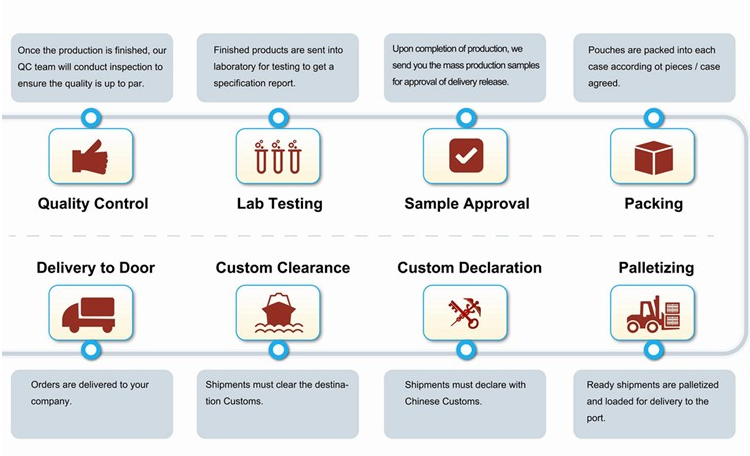

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)