Automatic Eye Drop Liquid Filling Machine

Eye drops filling machine

In the process of using the eye drop filling machine, you will experience the following benefits:

- The machine is easy to operate with computer control peristaltic filling, and dosage filling.

- It is easy to clean and sterilize thus causing no pollution.

- You can easily set the dosage of filling the vials with no necessity of stopping the machine.

- The machine has sensors that will detect the presence of a bottle before filling

- The filling part also has a shrinking function that will reduce dripping of medication after filling.

- You can closely monitor and adjust the functions of the machine through automatic display of the functions.

It has a PLC control panel that allows you to monitor and program all the functions including production speed.

- The machine is reliable in terms of filling process and materials thus increasing the durability.

- You can use the machine in the installation of a protection device according to your requirements.

- The construction of the machine is in accordance to the quality standards qualification standards.

- It has an adjustable, automatic temperature control system for controlling the temperature in the filling process.

This machine is completely automatic eye drop machine of filling, setting and sealing is composed of

Bottle setting machine, six filling nozzles machine, fixing inside stopper, outside cap and revolving lid.

The machine is applicable to the filling, cap-revolving of eye drop bottles of different shapes,

It has specialized structure for transporting bottles, bottle-in and bottle out, ensuring the stability

Of these eye drop bottles during transporting, filling and sealing. The machine can be also applicable to the filling and producing of different-shaped bottles of small dosage such as iodine, tincture and essential balm.

1. It is applicable to different-shaped bottles and plastic bottles: PP, PE, PVC, glass bottle

And mould bottle. The bottle in and bottle out has specialized structure. It doesn't drop bottles

Or nip bottles

2. PLC control, simple and easy to operate.

3. The part which touches the liquid medicine is made of 316L stainless material completely,

Meeting the requirement of GMP.

4. It can be connected with the bottle-washing machine and the label-attaching machine to form

A complete set of produce line.

Technical Parameters:

| Filling nozzles | 6 heads |

| Inside tuck pressing nozzle | 2 heads |

| Outside tuck capping nozzle | 2 heads |

| Filling capacity | 5-20ml |

| Filling precision | ≤ ± 0.5% |

| Filling production | 80-100 bottles/minute |

| Eligibility rate of inside tuck and outside tuck | ≥ 99% |

| Power | 1.5KW |

| Amount of pressing air | 0.6Mpa |

Bottle unscrambler

Cap feeder

Cap and stopper feeder

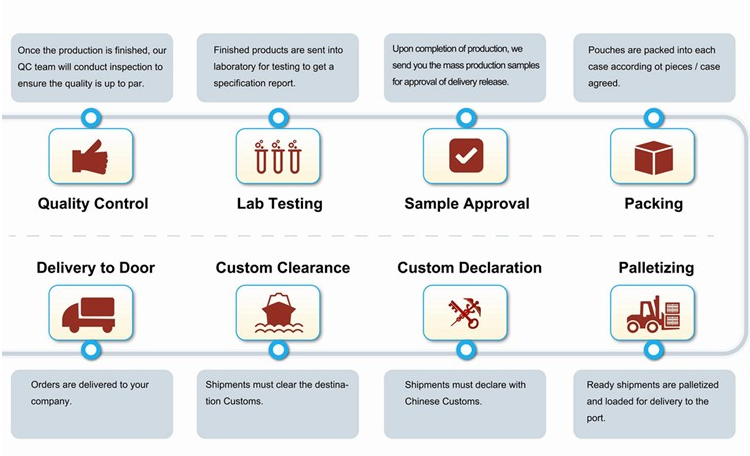

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)