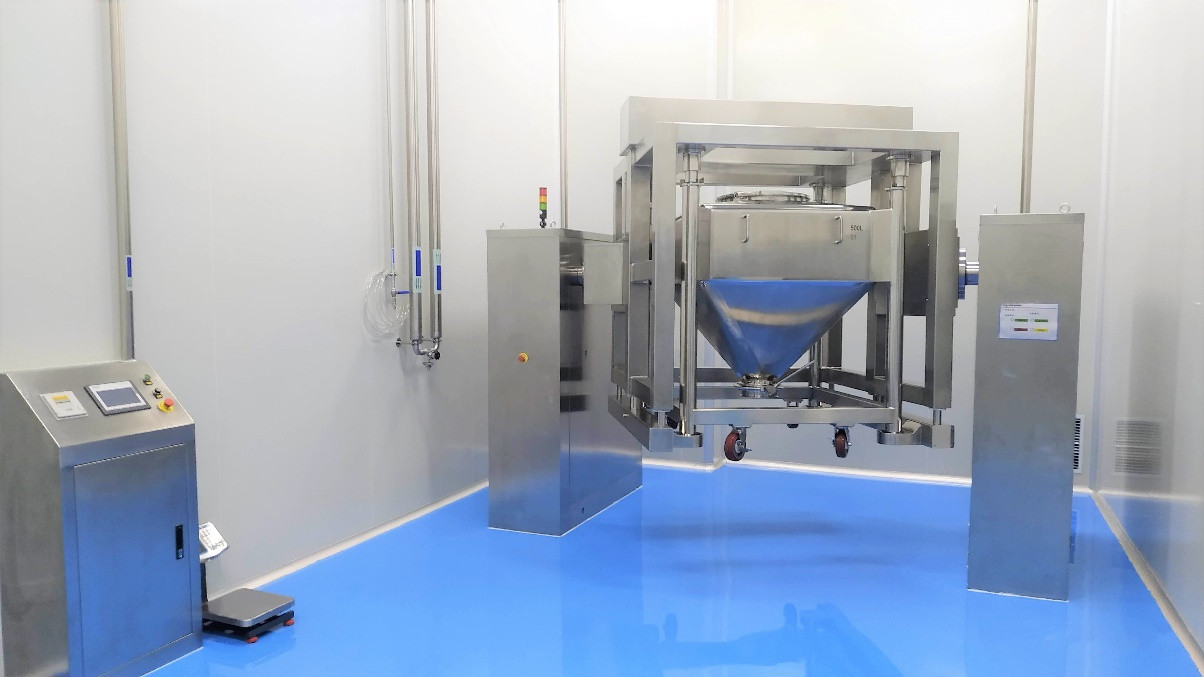

HTD double column lifting hopper mixer

1、 Equipment Overview

The HTD column hopper mixer is mainly used for mixing particles with particles, powders with powders, and particles with powders in the production of solid preparations. This machine has functions such as automatic lifting, mixing, and lowering. Equipped with a hopper mixer and multiple mixing hoppers of different specifications, it can meet the mixing requirements of multiple varieties and batches. It is an ideal equipment for pharmaceutical mixing and widely used in industries such as chemical and food.

2、 Working principle

The machine consists of a column, a base, a rotary fork, a drive, a brake, a control system, and other components. The mixing hopper is pushed into the rotary fork and the nut is locked. The control system is activated to lift the hopper to the mixing height and ensure reliable positioning. The drive system automatically mixes according to the set time, speed, and other data. After the mixing operation is completed, the rotary fork stops vertically, the hopper automatically descends to the ground, the whole machine stops, and process data is printed. Loosen the locking nut of the rotary fork and push out the hopper to the next process.

3、 Equipment features

1. Intelligent PLC control, graphical interface

2. The hopper has a smooth interior and is sealed to prevent dust from entering and cross contamination

3. Configure anti misoperation discharge butterfly valve

4. Easy to operate, maintain, and clean

5. The mobile hopper is convenient for transporting materials and loading and unloading

6. The mixing time and mixing speed can be adjusted through the touch screen to ensure good mixing effect. The system automatically locates, prints records, and provides fault prompts and alarms

7. Data can be stored and printed through a micro printer

Product Description

Automatic lifter mixing machine, developed by our company on the basis of advanced technology from Western European Countries, has a reasonable design, a compact structure, steady operation, high degree of homogeneity of material mixing and easy manipulation conforms with GMP standards of the medicine industry, fully satisfies the requirements for the enclosed production technology for solid preparations, and constitutes and ideal machine for mixing solid materials in slit form.

Features

1. It can apply four mixing drums of different volumes, meet the requirement for production in large batches and for different varieties, and serve different purposes with the same machine

2. This machine has an automatic inspection function. Through the use of PLC, touch screen display and frequency conversion speed regulation, the machine can automatically accomplish all the programs, and have a special man-machine interface and the function of storing and printing production date.

3. Through the use of mechanical transmission, it avoids oil leakage due to hydraulic transmission and environment pollution and medicine quality arising there from.

4. The mixing drum is detachable so that frequent material transfer is not needed during the production, to prevent flying dust and cross contamination, to optimize material transfer process, and to make washing easy.

5. This machine has double infrared detectors. AV alarm safety device and shock absorption device with easy and steady operation.

6. The whole machine is made of 304 Stainless Steel and its surface is treated against light pollution. All main components are of international brand.

| Rotate speed rpm | 3-12 |

| Dimensions(L*W*H) mm | 2020× 3060× 2380 |

| Working area(L*W*H) mm | 3000× 3060× 2800 |

| Power Kw | 9 |

| Loading percentage % | 50-70 |

| Max loading Kg | 1000 |

| Lifting speed mm/min | 780 |

| Applying tank L | 600 |

| Weight(including tank) Kg | 3000 |

| Mixing Precision % | ≥ 99 |

| Voltage V | 380 Three-phase five line(customized) |

| Control Voltage V | 220 single phase |

| Mixing time min | adjustable |

| Noise dB | ≤ 60 |

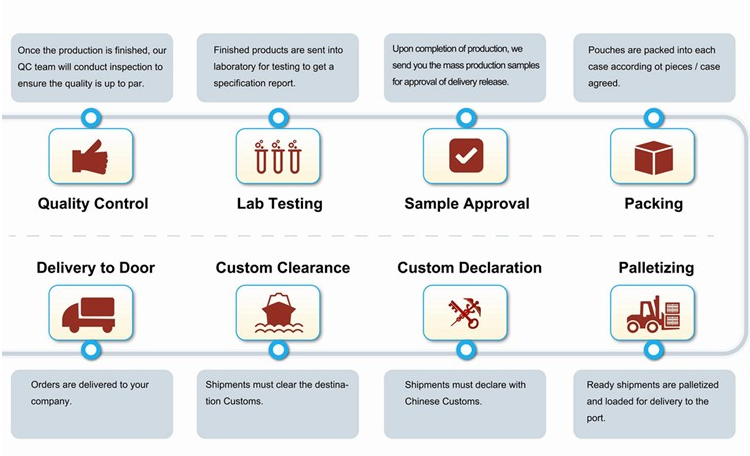

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)