BZJ-360 Centrifugal Granulator Coater

[Principle] This equipment is a new type of equipment developed on the basis of a rotating bed, equipped with automatic powder spraying and coating liquid automatic metering devices.

Typical applications: powder coating granulation, powder coating, granulation, spherical particle (pill) manufacturing, pill coating (film, enteric solubility, protective layer), masking and coloring of powder, granules, and pills

Pure Chinese medicine pellets

Equipment features:

Coating and pelletizing of particles. Coating and drying completed in one go

The coating of particles results in extremely high sphericity of the finished product

The coating liquefaction operation of particles is not easy to agglomerate and adhere

◆ Automatic control of liquid supply for particle coating, stable bed temperature without splashing

◆ Automatic spraying of coating powder for particles, accurate measurement

The coating of particles can handle low-density materials due to the compaction effect of centrifugal force

The coating process of particles has extremely high repeatability

◆ Design and manufacture in compliance with GMP standards

Function feature and the principle of action.

This machine can granulate and coat with powder material to spheroid, it can finish taste masking and colouring, etc coating well for powder ,granule and pellet, its design and manufacture are conformity with GMP normal. It is quick and full to clean and no cross pollution.

The main technical characteristics.

Number | Item | Unit | specification |

1 | Feeding Capacity | Kg/batch | 0.5-1.5 |

2 | Speed of rotor | rpm | 0-650 |

3 | Rotor diameter | mm | 360 |

4 | Motor | kw | 0.37 |

5 | Fan power | kw | 1.5 |

Safety Features:

Machine can’t run and Alarm as follows

Not earth

Compressed air press low as set

Can’t run the electrical heater before the blower run, and can’t off the electrical after off the blower

More pictures

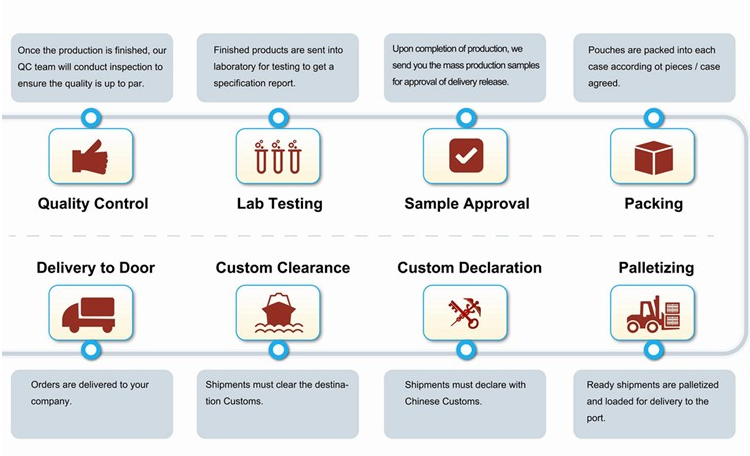

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)