Cosmetic Sachet Packaging Machine (ZS-130)

Vertical packaging machines and bag feeding packaging machines are widely used automated packaging equipment, which exhibit their own characteristics and advantages in different application scenarios and working principles.

Firstly, the vertical packaging machine, also known as the roll film bag making packaging machine, selects different weighing equipment according to the characteristics of the material to form a packaging unit. Its core work includes weighing, bag making, folding, filling, and sealing. This type of packaging machine is capable of handling packaging tasks for pillow bags, pin bags, punched bags, tote bags, and box bags. Users can customize according to specific needs and choose equipment models based on packaging capacity, ranging from 10g to 15000g. The measurement accuracy is usually between ± 0.2% and 0.5%. The advantage of a vertical packaging machine lies in its strong adaptability, which can handle a variety of materials and packaging forms, thus meeting the requirements of different industries for packaging efficiency and quality.

In contrast, bag packaging machines are used for packaging pre made bags, such as bags made of PE composite film, aluminum foil film, aluminum plated film, and other materials. The workflow includes steps such as bagging, coding, opening zippers (if any), opening bags, measuring and cutting materials, cleaning, heat sealing, and shaping. This packaging machine can pack various forms of packaging such as self-supporting bags, zipper bags, slanted mouth self-supporting bags, and flat bags. The advantage of bag packaging machines lies in their highly automated nature, which can effectively improve production efficiency and packaging consistency, making them particularly suitable for situations that require high-speed and high-precision packaging.

Cosmetic sachet packaging machine

Vertical packaging machine and bag feeding packaging machine

2. Automatically packing wettability powder, liquid, cream.

Cosmetic sachet packaging machine

Protecting the products completely according to international standards so as to prolong its Shelf-life.

Simple in working process, easy in operating due to the touched screen dialogue, swift in adjusting sizes,

It is easy to replace with three-side sealing or four-side sealing as required

The packing is flexible enough for automatically packing wettability powder, liquid, cream, catsup, grain, ect without losing attraction in package design or precision in measurement.

Basic parameter | |

Packing material | Complex film |

Packing products | powder, grain, liquid, suspension agent |

Producing speed | 40-80P/Min |

Precision in packing | within +/-1.5% |

Pouch width | 60-140mm |

Pouch height | 80-180mm |

Max volume | 160ml |

Roil film diameter | 400mm |

Electricity consumption | 3.5 kW |

| Air Consumption | 0.5m 3 /min |

Voltage | 380 V |

Weight | 800 kg |

Size | 2850mm×940mm×1400mm |

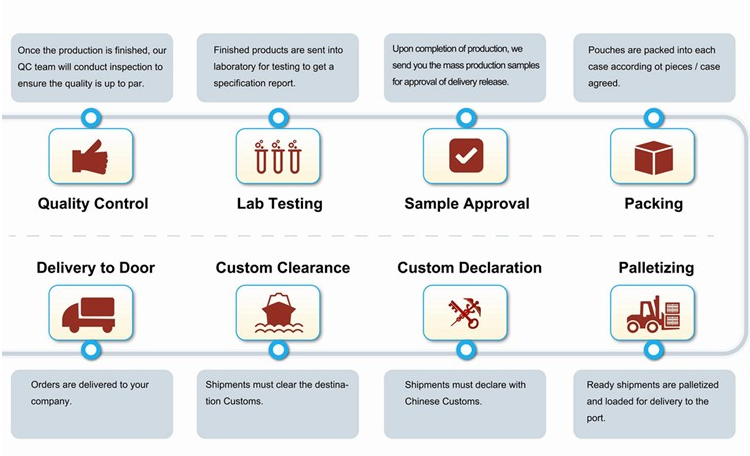

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)