LPG-5 Centrifugal Spray Dryer Drier Drying Equipment

Suitable for heat sensitive materials. Due to the parallel flow of liquid droplets and hot air, although the temperature of the hot air is high, the material will not overheat when water evaporates.

Widely applicable. A large number of materials with significant differences in physical properties are produced using this method. Such as polymers and resins; Dyes and pigments; Ceramics and glass; Rust removers and insecticides; Carbohydrates; Dairy products category; Blood and fish products category; Fertilizers; Organic and inorganic compounds; wait.

The air is converted into hot air through a heater, enters the hot air distributor at the top of the drying chamber, and then evenly enters the drying chamber, rotating in a spiral shape. At the same time, the material liquid is sent to the centrifuge at the top of the drying chamber, causing the material liquid to atomize into extremely small atomized droplets. The material liquid and hot air come into contact with each other, and the moisture evaporates rapidly, drying into finished products in a very short time. The finished product is discharged through the bottom of the drying tower and the cyclone separator, and the exhaust gas is extracted and discharged by the fan.

The drying speed is fast, and after atomization, the surface area of the material liquid is greatly increased. 65% -98% of the water can be evaporated instantly in the hot air flow, and the drying time is only 5-15 seconds. Specially suitable for drying heat sensitive materials, it can ensure the color, aroma, and taste of the materials

LPG-5 Centrifugal Spray dryer Drier Drying Equipment,LPG-5 centrifugal spray dryer spray drying equipment for small laboratory

PRINCIPLE OF WORKING

Air is turned into hot air through heater and enters into hot air distributor at the top of dry chamber and then enters into dry chamber and rotates in the state of helix. At the same time liquid of raw material is sent to centrifugal atomizer at the top of dry chamber through stepless variable screw pump. In which liquid of raw material atomizes small drops. Air and liquid of raw material flow and contact each other. The moisture vaporizes rapidly. Liquid of raw material is dried into finished product in a short time. The finished product is discharged through the bottom cyclone separator of drier and the wasted air is exhausted through fan.

FEATURES

The drying speed is very quick. When raw material is atomized, the surface area increases greatly. 65~98% of moisture can be vaporized in hot air stream momentary. The dry time to be used is only 5~15 seconds. Especially, it is suitable for drying thermal sensitive raw materials.

The size of finished product is uniform and the flow and solubility are good. The purity and quality of product are good too.

The operation is stable and simple. The regulation and control is very convenient. It is easy to realize automatic operation.

The operation process is simplified and the operation environment is superior and can avoid powder dust during the period of operation.

SCOPE OF APPLICATION

Chemical industry: Sodium (potassium) fluoride, alkali dyestuff and pigment, dyestuff intermediate, compound fertilizer, catalyst, amino acid, white black and so on.

Plastic resin: ABS emulsion liquid, urea formaldehyde resin, phenol formaldehyde resin, formaldehyde resin, PE, PVC and so on.

Foodstuff industry:

Egg and milk products: Rich lipoprotein powdered milk, cocoa powdered milk, baby meal, egg white, vitalize and so on, food and juice of plant, oat, chicken juice, coffee, crystalline tea, condiment and flavor, protein bean, earthnut protein, protein, hydrolysis and so on.

Sugar: Maize paste, maize starch, glucose, pectin, maltose, potassium seriate and so on.

Ceramic: Aluminum oxide, ceramic tile material, magnesium oxide, pencil stone and so on.

| MODEL | LPG-5 | LPG-25 | LPG-50 | LPG-100 | LPG-150 | LPG-200~2000 | ||||

| Inlet temperature | 140~350 ºC | |||||||||

| Outlet temperature | 80~90 ºC | |||||||||

| Water evaporation capacity(kg/h) | 5 | 25 | 50 | 100 | 150 | 200~2000 | ||||

| Revolution (rpm) | 25000 | 18000 | 18000 | 18000 | 15500 | 8000~15500 | ||||

| Diameter of atomizing disc (mm) | 50 | 120 | 120 | 120 | 150 | 180~240 | ||||

| Heat source | Electricity | Electricity | Steam+electricity, oil, fuel, gas | Solved by user | ||||||

| Max. power of electric heater (kw) | 9 | 48 | 72 | 81 | 99 | / | ||||

| Overall dimensions (m) | 1.8X0.93X2.2 | 3X3.2X5.1 | 3.7X3.2X5.1 | 4.6X4.2X6 | 5.5X4.5X7 | 1800 | ||||

| Recovery rate of dry powder (%) | ≥95 | |||||||||

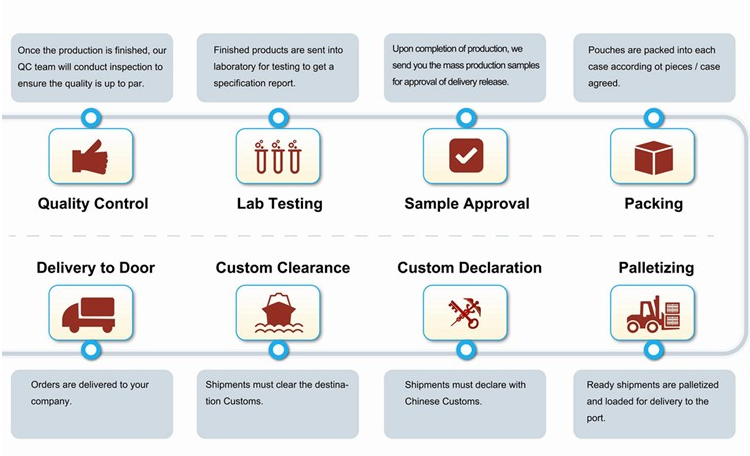

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![KE1PX$_SO]LLORZU3`DH8UW](http://img.yfisher.com/m5591/1716955263299568.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)