High Efficiency powder Filling and Stoppering Machine

The characteristics of powder automatic filling machines include many unique features in design and function, which enable them to handle various complex powder filling tasks. Its main characteristics include:

1. High precision measurement: The powder automatic filling machine adopts advanced measurement technology, such as screw metering, weighing sensors or flow meters, to ensure the accuracy of each filling. Whether it is a small or large dose, it can ensure that the amount of each powder is consistent.

2. Multi functional integration: These types of devices typically have multiple filling modes and functions, which can adapt to powder products with different characteristics, such as flour, milk powder, coffee powder, medicinal powder, etc. At the same time, the machine can integrate mixing, dust removal and other devices to ensure that the powder material remains uniform during the filling process.

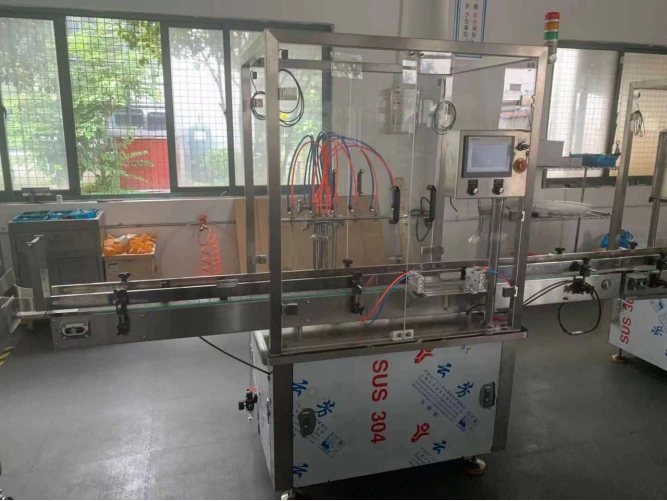

.Filling and stoppering machine

Integrated the filling and stoppering machine in one compact machine, it can finish the following procedure automatically , filling , stopper arranging, stopper putting, and stopper pressing, bottle out feeding, etc. the machine running smoothly, and stable function, accurate filling, and comply with GMP.

Yield capacity: 20-30pcs/min

Filling station: 2

Filling range: 100-200ml

filling tolerance :±1%

Capping station: ONE

Qualified cap putting: more or equal then 98%

Qualified capping: more or equal then 98%

Speed regulation: by inverter

power supply: 380V 50Hz

power: 1.8kw

outside dimension: 2440×1270×1550

powder Filling and capping machine

Technical parameter and main component

1.Bottle feeding machine

This machine is composed of turn table, bottle transfer channel, the machine order the bottle in one line, and delivery it to the washing machine. This machine can store the bottle, buffering the bottle, and change the bottle flow direction.

application: round bottle that can stand on the table steady

turntable dia. : φ900

transfer capability : comply with the washing machine

power supply: 220V 50HZ

power: 0.12KW

outside dimension: 950×1400×950

main component:the table, and surrounding plate is imported good quality SUS 304/2B

regulating motor: Linwan,Shanghai

button: Schneider

2.Filling and stoppering machine

Integrated the filling and stoppering machine in one compact machine, it can finish the following procedure automatically , filling , stopper arranging, stopper putting, and stopper pressing, bottle out feeding, etc. the machine running smoothly, and stable function, accurate filling, and comply with GMP.

Yield capacity: 20-30pcs/min

Filling station: 2

Filling range: 100-200ml

filling tolerance :±1%

Capping station: ONE

Qualified cap putting: more or equal then 98%

Qualified capping: more or equal then 98%

Speed regulation: by inverter

power supply: 380V 50Hz

power: 1.8kw

outside dimension: 2440×1270×1550

Main configuration:

the talbe and surrounding plate, and the part contacted with the bottle is imported good quality SUS 304/2B, the part contacted with liquid is 316L

Filling needle: 316L

Filling pump: Peristaltic pump

Inverter: Japan mitsubishi

Button: Schneider

Air switch: Schneider

AC contactor: Schneider

Speed reducer: goldgun, shanghai

Cam index: shangdong

The main motor:ABB

PLC: Siemens

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.