Aluminum Tube Filling and Sealing Machine

Main feature:

1. Driving part is enclosed under the platform, safe and no pollution.

With 12 stations and matching with manipulator, the machine is able to meet different type of tail folding, sealing requirements of plum tube, metal tube, plastic tube and laminated tubes. It is a multi-purpose machine.

2. Tube feeding, eye mark register, tube interior cleaning (optional).material filling, sealing (tail folding), batch number printing, finished products discharging can be performed automatically (the whole procedure).

3. Servo control makes it precise and convenient to adjust the filling amount by touch screen.

4. According to the different length of the tube, height of tube chamber can be adjusted easily by motor. With external reversal feeding system, makes tube charging more convenient and tidy.

5. The mechanical linkage photo sensor precision tolerance is less than 0.2mm.The chromatic aberration scope between tube and eye mark is reduced.

6. Photo-electronic, electric, pneumatic integrative control is applied with the machine. No tube, no filling .It gives an alarm when low pressure occurs. The machine stops automatically if tube error or open the safety door.

7. Three-layer jacket instant heater with inside air heating, It won't damage the pattern on outer wall of tube and achieves firm and beautiful sealing effect.

8.Fault alarm system included and the machine stops when overloading.

9. Numbering and the machine stops when amount is fixed.

Aluminum Tube Filling and Sealing Machine

Main Technical Parameters

Item | NF-60Z |

Tube material | Composite plastic tube, Alu tube |

Filling range (ml) | 5ml-200ml/tube (Adjustable) |

Filling accuracy | ≤± 1% |

Working speed | Up to 60 pcs/min |

Tube dia. (mm) | Φ10 -Φ50mm |

Tube length (mm) | 50-240mm (Max. length) |

Power of main machine | 380V/220V (As tailored) |

Working pressure | 0.55 - 0.65 Mpa |

Main motor power | 1.1 KW |

Heat up power | 3.0 KW |

Overall dimension | 2000 mm × 950 mm × 1900mm |

Net Weight | 850 kg |

More pictures

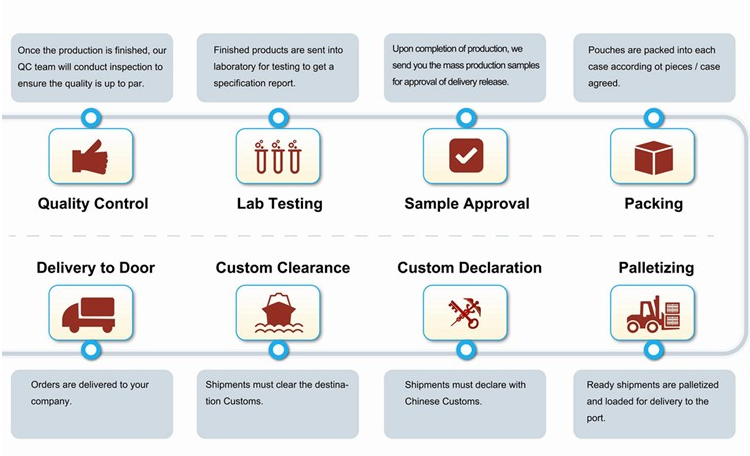

1.Nomally shipping steps:

2.Our packing and shipping:

Pre-Sales Service:

* Inquiry and consulting support.

*Quickly reaction.

*Factory inspection available anytime.

After-Sales Service:

*Prompt technical support

*Engineers available to service machinery overseas

*Installation &commissioning,good training for customers.

Q1.What's your delivery method?

A1:We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

Q2.What products can you provide?

A2:Our main product includes powder mixers,granulating equipments,drying equipments,capsule fillers,blister packing machines,tablet/capsule counting filling line,ampoule/vial/oral liquid filling line includes ultrasonic washing machine,sterilization oven,filling capping machine,labeling machine.

Q3. What's the payment terms?

A3:We will confirm the payment with you when quoting, like FCA, CIF or others.T/T is the main payment.

Q4.How do you ensure your product quality?

A4:We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

Q5:Does the machine power voltage meet buyers' factory power source?

A5: We can do it as your request.

Q6: Is it difficult to install the machine ?

A6: For standard small machines, the machines will be packed with no take apart, it comes to you to be a complete machine; you just need to connect power and compressed air to machine, then begin to operate the machine.

For large size machines, we will take the machine apart, on condition that we do our best to keep the machine easy to assembly.

You will get videos and instructions about installation of machine from us.

SUPM is a national high-tech enterprise integrating R&D, production, sales and related services of pharmaceuticals, food, cosmetics industries.

![(4[KDGL_NF%E6%2]D`4JYP](http://img.yfisher.com/m5591/171695525954e613.png)

![0OC}YRDYXP])TO]QMXZ48IJ](http://img.yfisher.com/m5591/171695526340fe25.png)

![RX2]L7{%NOW0`YXF9~)M{_G](http://img.yfisher.com/m5591/171695526519cd71.png)